The CarvWright system, a versatile and user-friendly computerised carving machine, is a popular tool for woodworkers and hobbyists. Known for its precision and ability to create intricate designs, the CarvWright uses its proprietary software to craft patterns and execute projects. However, many users wonder: Can I hard wire a CarvWright to a computer system?

This article explores the compatibility of CarvWright machines with hardwired computer connections, the steps required for integration, potential benefits, and challenges. We’ll provide a detailed overview to help you understand whether this setup is feasible and practical for your needs.

What Is a CarvWright Machine?

CarvWright is a CNC (Computer Numerical Control) carving machine designed for detailed woodworking projects. Its key features include:

- Ease of Use: Designed for users of all skill levels, including beginners.

- Advanced Software Integration: Uses the CarvWright Designer software to create and upload patterns.

- Versatile Applications: Can carve wood, plastics, and other soft materials.

- Portability: Compact and suitable for small workshops.

Typically, projects are transferred to the CarvWright via memory cards or USB devices, but users often seek more direct control by hardwiring it to a computer system.

Can You Hard Wire a CarvWright to a Computer System?

The simple answer is: Yes, it is possible, but it depends on the machine model, software compatibility, and your technical expertise. While CarvWright machines are designed to operate independently, with project files uploaded via removable storage, direct connection to a computer can be achieved under specific conditions.

How to Hard Wire a CarvWright to a Computer System

To establish a hardwired connection, you’ll need the appropriate hardware, software configurations, and an understanding of how CNC machines communicate with computer systems. Below is a step-by-step guide:

1. Assess Your CarvWright Model

Not all CarvWright models support direct computer connections. Check the user manual or specifications for:

- USB or Ethernet ports on the machine.

- Compatibility with live control features in the CarvWright Designer software.

2. Gather Necessary Equipment

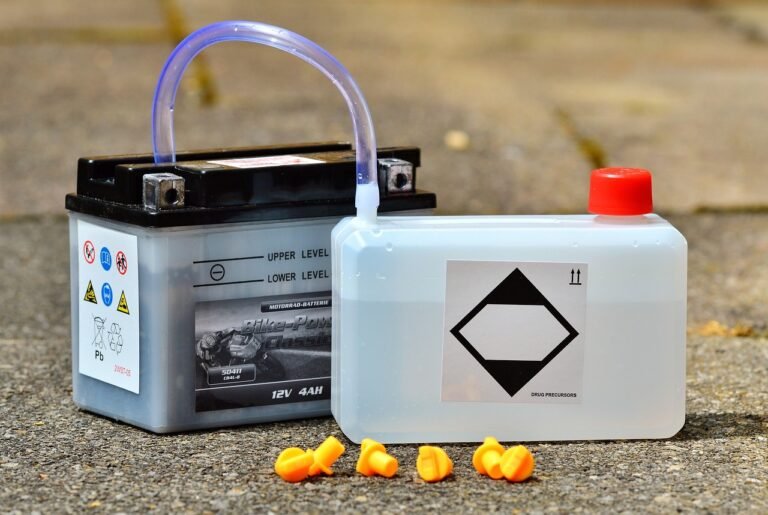

To hardwire your CarvWright to a computer system, you’ll need:

- A USB cable or Ethernet cable, depending on the available ports.

- A compatible computer with the CarvWright Designer software installed.

- Drivers or firmware updates (available on the CarvWright website).

3. Install and Update Software

Ensure the latest version of the CarvWright Designer software is installed on your computer. This software facilitates communication between the computer and the machine.

Steps:

- Download and install the CarvWright Designer software from the official website.

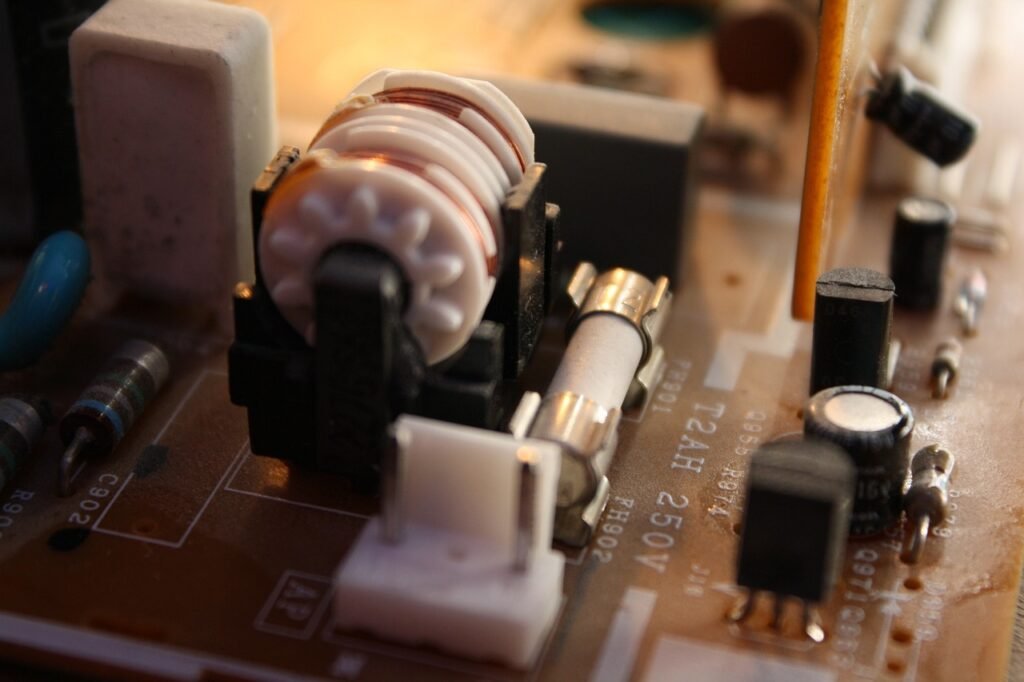

- Update the machine’s firmware if required. This ensures compatibility with direct connections.

4. Connect the Machine to the Computer

- USB Connection: Use a USB cable to connect the CarvWright directly to your computer.

- Ethernet Connection: For models supporting Ethernet, connect the machine to the computer via an Ethernet cable, configuring the network settings if necessary.

5. Configure Software Settings

- Open the CarvWright Designer software.

- Navigate to the settings menu and select the connected device as the primary carving machine.

- Test the connection to ensure the software recognizes the machine.

6. Test the Setup

- Upload a simple project through the hardwired connection to verify the communication between the computer and the CarvWright.

- Monitor the carving process to ensure smooth operation.

Benefits of Hardwiring a CarvWright to a Computer System

Hardwiring your CarvWright to a computer offers several advantages:

1. Real-Time Control

- Direct communication allows you to make adjustments to designs or machine settings during operation.

- Reduces the need to transfer files manually via memory cards.

2. Faster Data Transfer

- Speeds up the process of uploading large or complex designs, saving time compared to removable storage.

3. Enhanced Precision

- Allows for real-time monitoring of carving progress, reducing errors and improving accuracy.

4. Streamlined Workflow

- Eliminates the need for intermediate storage devices, simplifying the design-to-production process.

Challenges of Hardwiring a CarvWright

While hardwiring a CarvWright has clear benefits, there are potential challenges to consider:

1. Compatibility Issues

- Not all CarvWright models support direct computer connections. Ensure your machine is equipped with the necessary ports and features.

2. Technical Knowledge Required

- Configuring a hardwired connection may require familiarity with CNC systems, computer networking, or software troubleshooting.

3. Limited Support

- Some CarvWright machines are optimized for standalone operation. Manufacturer support for hardwired setups may be limited.

4. Risk of Interruptions

- Direct connections may be more susceptible to software crashes or computer malfunctions, potentially disrupting carving operations.

Alternative Solutions for CarvWright Users

If hardwiring your CarvWright proves impractical, consider these alternatives:

1. Wireless Connectivity

Some CarvWright models or third-party accessories allow wireless communication between the machine and computer, offering similar benefits to hardwiring without physical cables.

2. Memory Card Workflow

The traditional method of transferring designs via memory cards is simple and reliable, though less convenient for real-time adjustments.

3. Third-Party Controllers

Advanced users can integrate third-party CNC controllers with the CarvWright for enhanced capabilities, though this may void warranties or require significant technical expertise.

Conclusion

To answer the question, Can I hard wire a CarvWright to a computer system?, the answer is yes, provided your machine model supports it and you follow the necessary steps for setup. Directly connecting your CarvWright to a computer offers real-time control, faster data transfer, and improved workflow efficiency. However, compatibility and technical challenges may require additional effort or expertise.

For those seeking greater control over their carving projects, exploring a hardwired connection is worth considering. If unsure, consult your CarvWright’s manual, contact customer support, or seek assistance from a professional technician to ensure a seamless integration.